Construction of the Pile

Construction of the main pile at Chicago started in November. The project gained momentum, with machining of the graphite blocks, pressing of the uranium oxide pellets, and the design of instruments. Fermi's two "construction" crews, one under Zinn and the other under Anderson, worked almost around the clock. V. C. Wilson headed up the instrument work.

Original estimates as to the critical size of the pile were pessimistic. As a further precaution, it was decided to enclose the pile in a balloon cloth bag which could be evacuated to remove the neutron-capturing air. This balloon cloth bag was constructed by Goodyear Tire and Rubber Company. Specialists in designing gasbags for lighter-than-air craft, the company's engineers were a bit puzzled about the aerodynamics of a square balloon. Security regulations forbade informing Goodyear of the purpose of the envelope and so the Army's new square balloon was the butt of much joking.

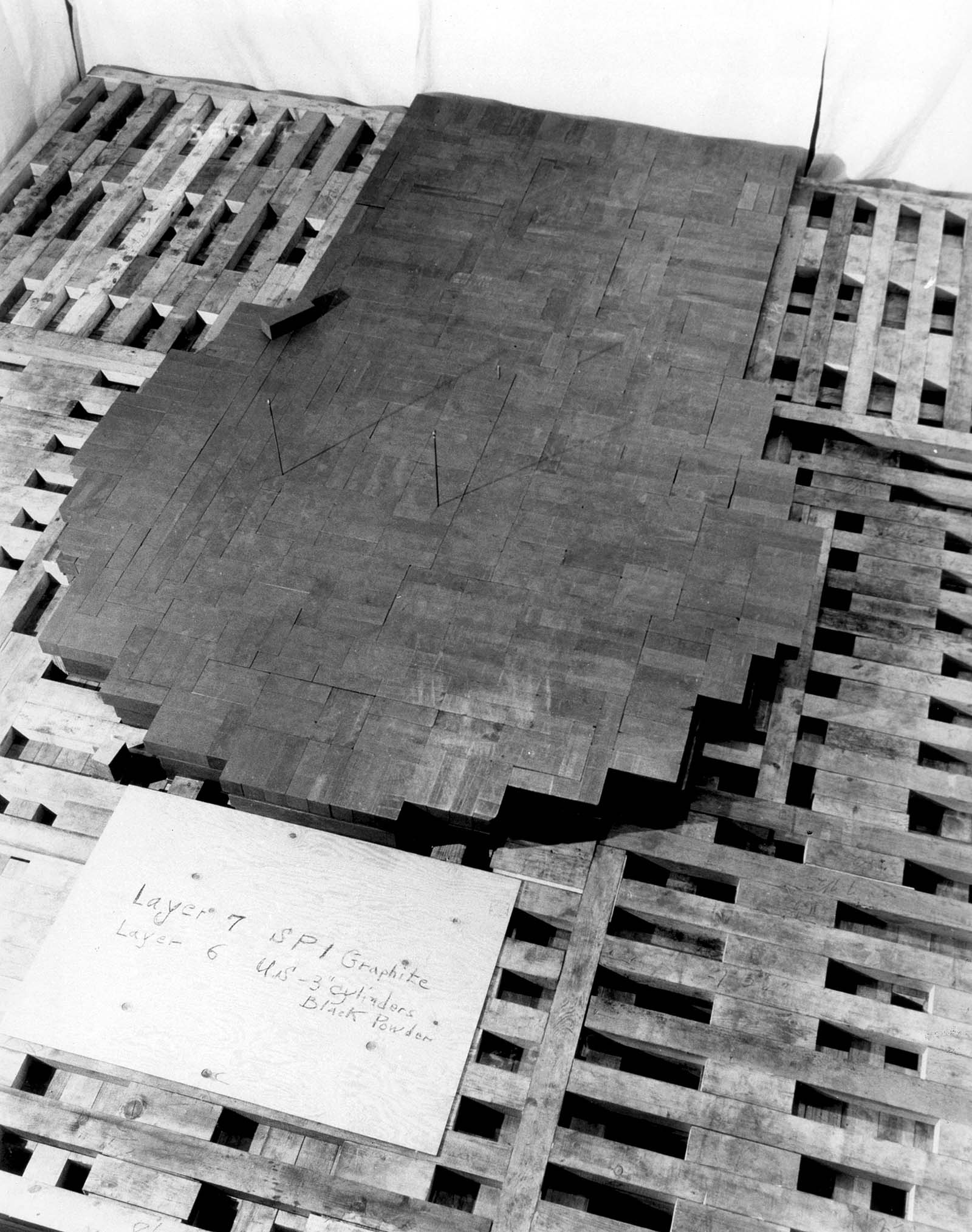

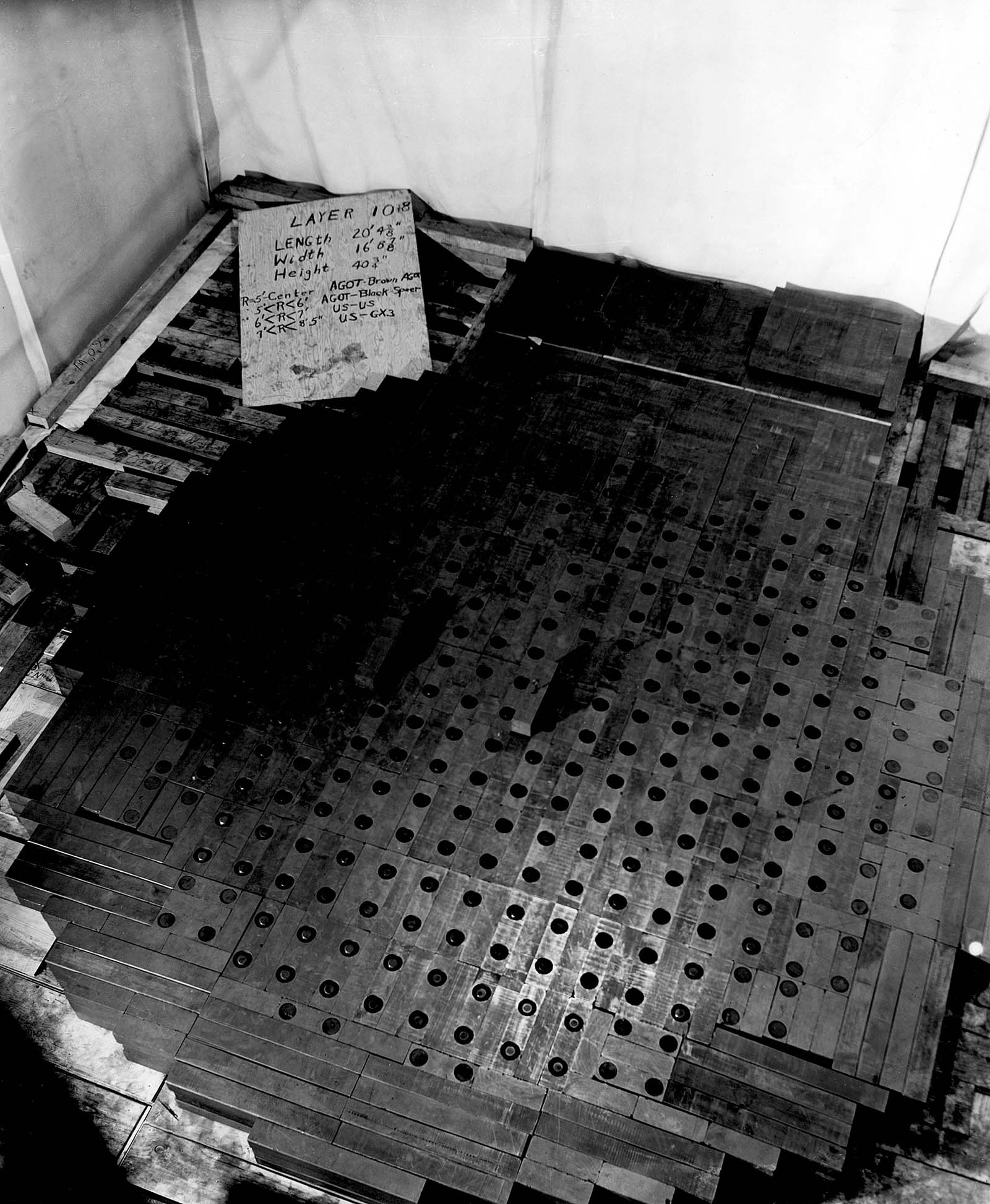

The bag was hung with one side left open; in the center of the floor a circular layer of graphite bricks was placed. This and each succeeding layer of the pile was braced by a wooden frame. Alternate layers contained the uranium. By this layer-on-layer construction a roughly spherical pile of uranium and graphite was formed.

Facilities for the machining of graphite bricks were installed in the West Stands. Week after week this shop turned out graphite bricks. This work was done under the direction of Zinn's group, by skilled mechanics led by millwright August Knuth. In October, Anderson and his associates joined Zinn's men.

Describing this phase of the work, Albert Wattenberg, one of Zinn's group, said: "We found out how coal miners feel. After eight hours of machining graphite, we looked as if we were made up for a minstrel. One shower would remove only the surface graphite dust. About a half-hour after the first shower the dust in the pores of your skin would start oozing. Walking around the room where we cut the graphite was like walking on a dance floor. Graphite is a dry lubricant, you know, and the cement floor covered with graphite dust was slippery."

Before the structure was half complete, measurements indicated that the critical size at which the pile would become self-sustaining was some-what less than had been anticipated in the design.